Supercharged Mugen Lude (03/06/14 Update!)

Posted: Tue Aug 24, 2010 11:47 pm

My Supercharged Mugen Lude

CONTENTS (with links to posts)

Page 1 = BUILD PART 0 – My Preludes History

Page 1 = BUILD PART 1 – Introduction

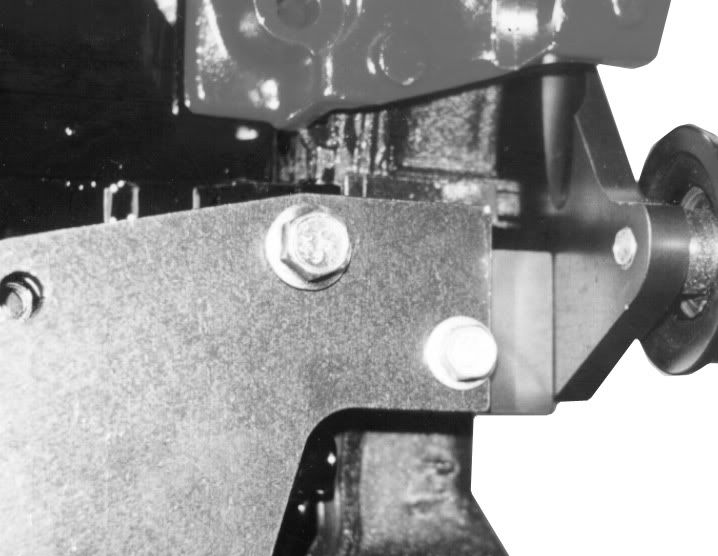

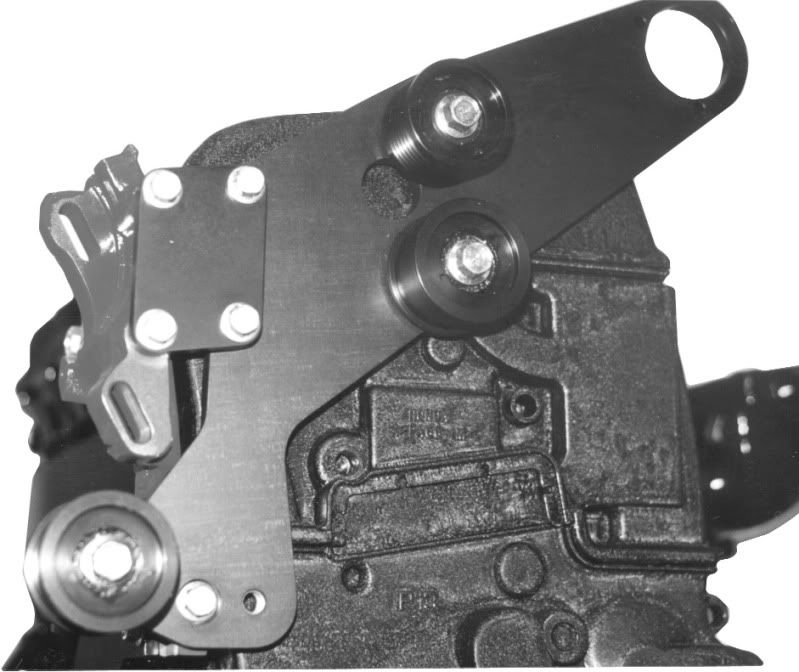

Page 1 = BUILD PART 3 – Does 5th gen Jackson Racing SC Fit the 4th gen

Page 1 = BUILD PART 3 – Build Parts – Jackson Racing Supercharger Kit

Page 1 = BUILD PART 4 – Build Parts (Cont’d) – Fuelling

Page 1 = BUILD PART 4 – Build Parts (Cont’d) – Tuning

Page 3 = BUILD PART 4 – Build Parts (Cont’d) – Transmission

Page 3 = BUILD PART 4 – Build Parts (Cont’d) – Cooling

Page 4 = BUILD PART 4 – Build Parts – Miscellaneous Parts

Page 4 = BUILD PART 5 – Build – Compression Test

Page 4 = BUILD PART 5 – Build – Engine Parts Removal (A/C, EGR, C/C, Resonator Bypass)

Page 5 = BUILD PART 5 – Build – Engine Parts Removal (EGR)

Page 5 = BUILD PART 5 – Build – Battery Relocation + PAS removal

Page 7 = BUILD PART 4 – Build Parts (Cont’d) – Brakes

Page 7 = BUILD PART 4 – Build Parts (Cont’d) – Interior

Page 10 = BUILD PART 4 – Build Parts (Cont’d) – Electrical and Misc

Page 11 = BUILD PART 4 – Build Parts (Cont’d) – Wheels

Page 12 = BUILD PART 4 – Build Parts (Cont’d) – Suspension

Page 12 = BUILD PART 4 – Build Parts (Cont’d) – Fuelling Again

Page 14 = BUILD PART 4 – Build Parts (Cont’d) – More Cooling

Page 14 = BUILD PART 4 – Build Parts (Cont’d) – Intake & Exhaust

Page 16 = BUILD PART 4 – Build Parts (Cont’d) – Intake & Evap system removal

Page 17 = BUILD PART 5 – Build (Cont’d) – JRSC parts / Intake refurb & more

Page 20 = BUILD PART 5 – Build (Cont’d) – More removals – Rad, PAS, Fuel system

Page 26 = BUILD PART 5 – Build (Cont’d) – Garage distractions & more

Page 28 = BUILD PART 5 – Build (Cont’d) – ABS removal

Page 30 = BUILD PART 5 – Build (Cont’d) – More things to remove!

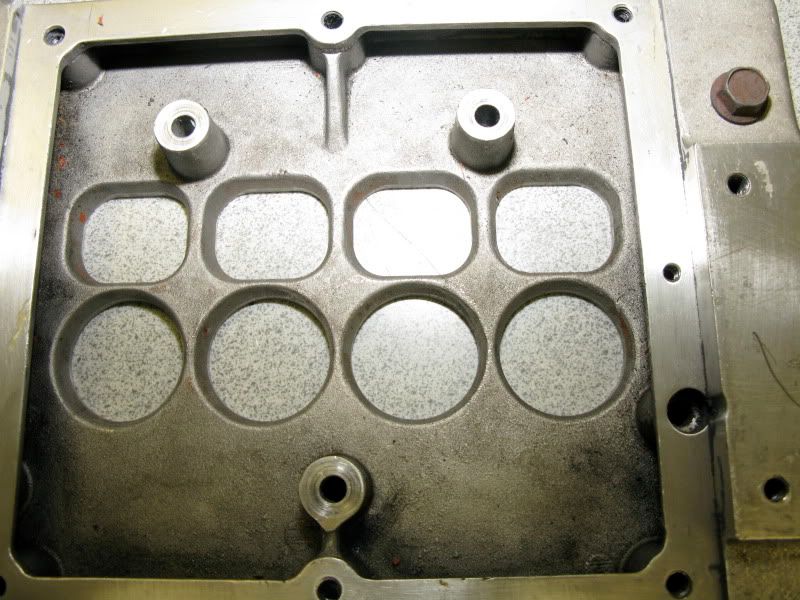

Page 31 = BUILD PART 5 – Build (Cont’d) – Porting Parts

Page 32 = BUILD PART 4 – Parts (Cont’d) - Another Parts Roundup

Page 36 = BUILD PART 4 – Parts (Cont’d) - Seats, Brakes, Wheels

Page 36 = BUILD PART 4 – Parts (Cont’d) – More wheels…

Page 39 = BUILD PART 5 – Build (Cont'd) - Reality Check

Ongoing Spec:

Key

Fitted

Waiting to be fitted

Ordered

Not yet ordered

Not made yet – custom!

General

Base Car = UKDM BB1 Honda Prelude 2.2 VTEC 4ws

Date car was bought = August 2003

Engine

Mugen Version 1 Billet Oil Cap (Genuine)

Mugen Reservoir Covers (Genuine) – to brake and clutch reservoir

VTEC Rocker Cover Resprayed OEM

Red Kevlar / Carbon Weave Plug Cover

Samco Red Silicone Breather Pipes

Airconditioning Removal – Gates Micro-V 6PK913 belt to bypass compressor

Jackson Racing Supercharger Kit!!!

Full Engine Gasket Set

Gates Powergrip Cambelt and Balancer Belt

KS Tuned manual tensioner

Oil filter relocation and 19 row oil cooler + all black AN10 lines and fittings

Hamp Oil Filter

Motul 8100 X-Cess 10W-40 Semi-synthetic Oil

New Water Pump

Works Engineering Cam Seal (Triple O-ring seal)

Tegiwa Imports – Engine Dress Up Black Bolts & Black Washers (Pack of 5 x 3 = 15nr)

Tegiwa Imports – Rocker Cover Dress Up Black Dome Bolts (pack of

Silicone Vacuum Hosing in Black from SFS Hoses

Spare Engine Rocker Cover – Now Smoothed and AN10 breather fittings awaiting to be welded on

Spare Engine Rocker Cover Powder Coated Black (Temporary until above one is finished)

Spare Engine – H22A (for round 2 of my plans)

Innovative Motorsports Replacement Mount Kit – 95A race urethane

AN10 Braided Lines from Torques UK – for rocker cover venting to Catch Can

Performance Autoworks Baffled Sump

Custom Aluminium Ventilated Catch Can with AN10 ports

106pete special custom chargecooler

Transmission

UKDM standard M2A5 gearbox

ATR U2Q7 gearbox – LSD + better ratios + higher final drive

JUN 11lb ultralight flywheel

ACT Street Clutch and HD Pressure Plate

I-Tuned Goodridge Custom Braided Clutch Line (deletes damper)

Tegiwa Imports Magnetic Gearbox Sump Plug

Torco MTF Gearbox Oil – 2 litres from Nimbus Motorsports

New Clutch Slave Cylinder (Import Car Parts)

Forbidden Motorsports Short Shifter (or similar)

New Oil Seals

Intake & Exhaust

No exhaust or manifold currently fitted

Apexi Power Intake Induction Kit Filter and Modified Elbow

Tanabe Carbon Fibre Induction Kit Tubing (Short Ram)

Hondata Heatsheild Gasket

CNT 68mm throttle body (tapers out to 71mm) + new TPS sensor

Mikalor W2 Hose Clamps (for carbon intake tubing to throttle body) – 85mm+

Silicone Hose Joiner 3” to 3” in Black from SFS Hoses

New Stainless Steel Manifold Studs

3” Catback Exhaust System – tubing sourced by tonydpp & welded by Solid Fabs

3” Decat Pipe from a Mitsibushi Evo 4-6

Custom Solid Fabrications Manifold & Downpipe – 4-1 Design to a 3” Collector

BGA Manifold Gasket (Engine Block to Manifold) – three skin metal gasket

New 3” Evo Flange Exhaust Gaskets x 3 (3” collector and either side of decat)

New OEM Honda O2 Sensor (from a Civic 1.6 VTEC 5 door – same but slightly longer than the Prelude’s)

Used OEM Mitsibushi Evo 6 Catalyst Converter (For MOT emissions test)

Fuelling & Ignition

Denso Iridium Spark Plugs

Nology Hotwire Ignition Leads – Red colour

550cc RC Saturated Injectors

New Injector Seal Kit

AEM Fuel Rail – Silver

Torques UK – Custom AN6 Fuel Supply Line and Inline Fuel Filter

Fuel Pressure Gauge (1/18th NPT fitting to AN line fitting adaptor

HRC 255lph Fuel Pump

Spark Plugs – 1 step colder, 2 sets = 1 x NGK Copper & 1 x Denso Iridiums

Tuning / Electrical

Hondata S300 / P28 (with PWM boost components installed)

Jackson Racing air/fuel ratio gauge (made by Auto Meter)

Jackson Racing Oil Temperature Gauge (made by Auto Meter)

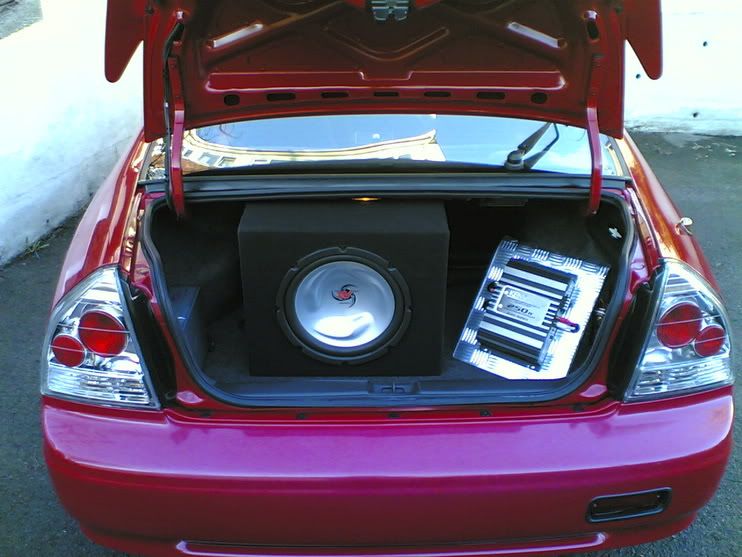

Odyssey PC680 Race Battery (for boot mounting)

Aluminium Battery Mount / custom cut off, circuit breaker, voltage tester unit / 0 gauge wiring, fuses, etc

AEM UEGO Wideband Lambda Gauge

Dyno Tune Digital Boost Gauge (accurate to within 0.1psi boost)

OEM EL Gauges, Loom, Switch, Dimming Box, etc

Pivot Blue Engine Start Button

Autometer Oil Pressure Gauge

New high & low tone horns

Cooling

Mugen Type D 1.3 bar Radiator Cap (Genuine)

Aluminium Thicker Core Radiator (97-01 5th gen fitment)

Tegiwa Import – Aluminium Radiator Stays (for top mounts)

SPAL 2 x 11” Radiator Slimline Fans

Revotec Rad Fan Fitting Kit x 2

Mugen Type F 1.3 Bar Radiator Cap (Genuine)

Mishimoto black Radiator Hoses

QH Thermostat (with new gasket)

Mikalor W2 Hose Clamps (for rad hoses) – 42mm

Millers Rxtra Cool Coolant Additive (Like Redline Watter Wetter)

AEM Water Injection Kit – No AEM Tank

5 metres of extra 6mm O.D. / 4mm I.D. Nylon High Pressure Hose for Water Injection – In Red

6mm Nylon ‘P’ Clips (for routing water injection hose from boot to engine bay)

10 Litre Red Metal Jerry Can for Water Injection Fluid

5 Litres of Distilled Water (for 50/50 mix of Methanol/Water)

5 Litres of Methanol (for 50/50 mix of Methanol/Water)

(Might not need all of the water injection stuff if chargecooler works)

Suspension

D2 36 way Adjustable Coilovers

Fully working OEM Honda Four Wheel Steering System (4WS)

Suspension Techniques uprated 25mm Sway Bars / Anti Roll Bars – Front & Back

2WS Rear Sub Frame, Control Arms, etc

Energy Suspension Master Bushing Set Installed into a Spare Set of Arms, etc – Including Rear Trailing Arms

Spoon Rear Upper Strut Brace

New Wheel Bearings

Megan Racing Adjustable Rear Toe Arms

Innovative Motorsports Competition Bar (Traction Bar)

Ultra Racing front under brace

Ultra Racing rear under brace

Exterior / Body

Full Restoration & Respray in OEM Milano Red Paint (Including Gloss Black Roof and Roof Rails, Boot OEM Spoiler & Bades Removed and Hole Smoothed, New Front Screen, Seals, Trims & Clips from Honda)

Mugen Front Bumper and Restored Mugen Emblem (Genuine)

Mugen Front Bumper / Headlight Plastic Covers (Copies)

Mugen Rear Spoiler and Restored Mugen Fixings and Emblem (Genuine)

Mugen Number Plate Screws / Washers (Genuine) x 8 for number plates and bumper fixings

Mugen Fuel Filler Cap Cover (Genuine)

Carbon Creations Carbon Fibre Bonnet – OEM Style[color]

EP Racing Bonnet Spacers

Carbon Fibre Fuel Flap

JDM Number Plates (Originals from Japan – Show use only)

Honda OEM JDM Door Window Wind Deflectors

Honda OEM UKDM Bodykit – Side Skirts

Honda OEM UKDM Bodykit – Rear Lip Skirt

Crystal clear bumper inserts - lost one side and used amber repsrayed red

Crystal clear side repeaters

Front Wiper Arms Resprayed Satin Black

Rear Wiper and Motor Removed and Blanking Grommet Installed

Aerial and Blanking Grommet Installed

Mugen Side Skirts Resprayed in Milano Red (Genuine) – just need to fabricate the last couple of small brackets

Aerocatch Bonnet Pins (Lockable)

Detango’d OEM Lights

JDM OEM Boot Number Plate Recess Panel

Mugen Side Sill Aluminium Plates (Genuine)

Honda Jazz Washer Jets

OEM Side Repeaters sprayed black

Spoon Style Fibreglass Mirrors (+ Civic Baseplates)

Spare Prelude Wing Mirrors to Butcher and make custom baseplates

AeroDynamics Carbon Fibre Sunroof Panel

Seibon Carbon Fibre Boot / Trunk

Varis Mitsubishi Evo 4-6 rear lower diffuser and side vortex generators

Wheels

No wheels currently!

Tegiwa Imports – Red Anodized Aluminium Extended Wheel Nuts

4 x 17” x 8” Volk Racing Group A Evolution 2 Alloys – 3 Piece Split Rims with Magnesium Baskets

1 x 17" x 7" Buddy Club SF Alloy Wheel (Spare Wheel)

4 x 17” x 7.5J Offset 38 – Antera 301 Alloys - Finished in Powder Coated Black with red vinyl rim tape

2 x 225/45/17 Yokohama Advan A048 track tyres (need another two!)

Interior

Mugen SW2 Steering Wheel with Integrated Cruise Control / Horn Pad (Genuine)

HKB Steering Boss with Integrated Cruise Control Buttons (Rare)

No seats currently!

Fidanza Short Throw Shift Adaptor

Custom Moulded 3 Gauge A-Pillar Pod Painted Milano Red

Front and Rear Door Card Inserts Retrimmed in Red Leathette

Handbrake Gaitor Retrimmed in Red Leatherette

Shifter Gaitor Retrimmed in Red Leatherette

JDM Flare & Holder to Passenger Side

Integra Type R Style Chrome Gearknob

Post-Facelift (94-) Chrome Door Handles

Pre-Post Facelift Transition Centre Console Conversion & Arm Rest (Rare)

Added Third Interior High Level Brake Light and Rear Roof Lining Panel

Rear interior part stripped

Centre Arm Rest - Finish Retrim

Recaro Sportline Top Fuel Specials - Grey/Black/Red

Recaro one-off 4th gen Prelude sliding seat rails (fitted to Top Fuel Recaros)

Recaro TS-G bucket seat (Japan only market seat) - Blue/Black

Recaro Japan bucket seat side mounts (Japan only market) - Black

Bride MO Sliding Seat Mounts (to fit the bucket seat to + spare)

Takata MPH-341 harness - 3" shoulder and lap straps (Genuine)

Takata 6 point V-style crotch strap (Genuine)

Tram Road Motors special Harness bar

FIA approved harness eyebolts & backing plates (4Nr for drivers 6 point harness)

Cargo Nets x 2

Brakes

Legend Calipers – Refurbed with Brakesint Kits

EBC Redstuff Pads Front

Ebay Cheap Front Discs Drilled & Grooved

EBC Redstuff Pads Rear

Bremtech Rear Discs – Drilled & Grooved

ABS removed

K Sport 6 pot Calipers - 306mm discs + Ksport pads + braided brake lines

Integra DC5 Rear Brake Calipers – Fully Refurbished

Tarox G88Rear Discs

Ferrodo DS2000 Pads Rear

Willwood Brake Bias Valve

Goodridge braided brake lines

Copper/Nickel Brake Piping to install new lines – 25ft

Various Brake items – Flare Nuts, Cutter, Bender, Flare Wrenches

8mm Aluminium ‘P’ Clips with Rubber Protector

ICE

Ripspeed 7 inch widescreen Flip Out Monitor DVD Player

JVC 100 Watts 6 ¼” 2 Way Mid Speakers to Rear Shelf

Pioneer 120 Watt 6 x 9” 2 Way Speakers in Custom Mounts (orig. 6 ¼”) in Doors

Performance

Previously dyno’d at 205.8 bhp & 152 lb/ft

¼ mile best = 15.5 seconds @ 90mph trap speed (not with a lot of mods and the weight saving I’ve done since)

Tracked as Castle Combe Circuit, Wiltshire UK

Hopeful target power after supercharger build = 300bhp+ & 210+ Torque

Hopeful target ¼ mile after supercharger build = below 13.5 Seconds

ENGINE BUILD FOR ANOTHER DAY

- Jackson Racing Supercharger kit + Motorvations 2" jackshaft pulley + Accord crank pulley = Approximately 12psi

- 106pete custom chargecooler from a Landrover SC V8 + heat exchanger rad, hoses, pump, reservoir, etc

- Benson sleeved H22A1 - 88mm bore + build up with spare H22A engine parts (50mm crank)

- Wiseco 11.5:1 88mm pistons + rings, sleeves

- Golden Eagle rods + ARP bolts

- ARP head stud kit

- Standard H22 head (unless I try a Type S / H22A7 head???)

- Full engine gasket set

- KS Tuned manual tensioner (transferred from old engine)

- Gates Powergrip belts

- ACL bearings

CONTENTS (with links to posts)

Page 1 = BUILD PART 0 – My Preludes History

Page 1 = BUILD PART 1 – Introduction

Page 1 = BUILD PART 3 – Does 5th gen Jackson Racing SC Fit the 4th gen

Page 1 = BUILD PART 3 – Build Parts – Jackson Racing Supercharger Kit

Page 1 = BUILD PART 4 – Build Parts (Cont’d) – Fuelling

Page 1 = BUILD PART 4 – Build Parts (Cont’d) – Tuning

Page 3 = BUILD PART 4 – Build Parts (Cont’d) – Transmission

Page 3 = BUILD PART 4 – Build Parts (Cont’d) – Cooling

Page 4 = BUILD PART 4 – Build Parts – Miscellaneous Parts

Page 4 = BUILD PART 5 – Build – Compression Test

Page 4 = BUILD PART 5 – Build – Engine Parts Removal (A/C, EGR, C/C, Resonator Bypass)

Page 5 = BUILD PART 5 – Build – Engine Parts Removal (EGR)

Page 5 = BUILD PART 5 – Build – Battery Relocation + PAS removal

Page 7 = BUILD PART 4 – Build Parts (Cont’d) – Brakes

Page 7 = BUILD PART 4 – Build Parts (Cont’d) – Interior

Page 10 = BUILD PART 4 – Build Parts (Cont’d) – Electrical and Misc

Page 11 = BUILD PART 4 – Build Parts (Cont’d) – Wheels

Page 12 = BUILD PART 4 – Build Parts (Cont’d) – Suspension

Page 12 = BUILD PART 4 – Build Parts (Cont’d) – Fuelling Again

Page 14 = BUILD PART 4 – Build Parts (Cont’d) – More Cooling

Page 14 = BUILD PART 4 – Build Parts (Cont’d) – Intake & Exhaust

Page 16 = BUILD PART 4 – Build Parts (Cont’d) – Intake & Evap system removal

Page 17 = BUILD PART 5 – Build (Cont’d) – JRSC parts / Intake refurb & more

Page 20 = BUILD PART 5 – Build (Cont’d) – More removals – Rad, PAS, Fuel system

Page 26 = BUILD PART 5 – Build (Cont’d) – Garage distractions & more

Page 28 = BUILD PART 5 – Build (Cont’d) – ABS removal

Page 30 = BUILD PART 5 – Build (Cont’d) – More things to remove!

Page 31 = BUILD PART 5 – Build (Cont’d) – Porting Parts

Page 32 = BUILD PART 4 – Parts (Cont’d) - Another Parts Roundup

Page 36 = BUILD PART 4 – Parts (Cont’d) - Seats, Brakes, Wheels

Page 36 = BUILD PART 4 – Parts (Cont’d) – More wheels…

Page 39 = BUILD PART 5 – Build (Cont'd) - Reality Check

Ongoing Spec:

Key

Fitted

Waiting to be fitted

Ordered

Not yet ordered

Not made yet – custom!

General

Base Car = UKDM BB1 Honda Prelude 2.2 VTEC 4ws

Date car was bought = August 2003

Engine

Mugen Version 1 Billet Oil Cap (Genuine)

Mugen Reservoir Covers (Genuine) – to brake and clutch reservoir

VTEC Rocker Cover Resprayed OEM

Red Kevlar / Carbon Weave Plug Cover

Samco Red Silicone Breather Pipes

Airconditioning Removal – Gates Micro-V 6PK913 belt to bypass compressor

Jackson Racing Supercharger Kit!!!

Full Engine Gasket Set

Gates Powergrip Cambelt and Balancer Belt

KS Tuned manual tensioner

Oil filter relocation and 19 row oil cooler + all black AN10 lines and fittings

Hamp Oil Filter

Motul 8100 X-Cess 10W-40 Semi-synthetic Oil

New Water Pump

Works Engineering Cam Seal (Triple O-ring seal)

Tegiwa Imports – Engine Dress Up Black Bolts & Black Washers (Pack of 5 x 3 = 15nr)

Tegiwa Imports – Rocker Cover Dress Up Black Dome Bolts (pack of

Silicone Vacuum Hosing in Black from SFS Hoses

Spare Engine Rocker Cover – Now Smoothed and AN10 breather fittings awaiting to be welded on

Spare Engine Rocker Cover Powder Coated Black (Temporary until above one is finished)

Spare Engine – H22A (for round 2 of my plans)

Innovative Motorsports Replacement Mount Kit – 95A race urethane

AN10 Braided Lines from Torques UK – for rocker cover venting to Catch Can

Performance Autoworks Baffled Sump

Custom Aluminium Ventilated Catch Can with AN10 ports

106pete special custom chargecooler

Transmission

UKDM standard M2A5 gearbox

ATR U2Q7 gearbox – LSD + better ratios + higher final drive

JUN 11lb ultralight flywheel

ACT Street Clutch and HD Pressure Plate

I-Tuned Goodridge Custom Braided Clutch Line (deletes damper)

Tegiwa Imports Magnetic Gearbox Sump Plug

Torco MTF Gearbox Oil – 2 litres from Nimbus Motorsports

New Clutch Slave Cylinder (Import Car Parts)

Forbidden Motorsports Short Shifter (or similar)

New Oil Seals

Intake & Exhaust

No exhaust or manifold currently fitted

Apexi Power Intake Induction Kit Filter and Modified Elbow

Tanabe Carbon Fibre Induction Kit Tubing (Short Ram)

Hondata Heatsheild Gasket

CNT 68mm throttle body (tapers out to 71mm) + new TPS sensor

Mikalor W2 Hose Clamps (for carbon intake tubing to throttle body) – 85mm+

Silicone Hose Joiner 3” to 3” in Black from SFS Hoses

New Stainless Steel Manifold Studs

3” Catback Exhaust System – tubing sourced by tonydpp & welded by Solid Fabs

3” Decat Pipe from a Mitsibushi Evo 4-6

Custom Solid Fabrications Manifold & Downpipe – 4-1 Design to a 3” Collector

BGA Manifold Gasket (Engine Block to Manifold) – three skin metal gasket

New 3” Evo Flange Exhaust Gaskets x 3 (3” collector and either side of decat)

New OEM Honda O2 Sensor (from a Civic 1.6 VTEC 5 door – same but slightly longer than the Prelude’s)

Used OEM Mitsibushi Evo 6 Catalyst Converter (For MOT emissions test)

Fuelling & Ignition

Denso Iridium Spark Plugs

Nology Hotwire Ignition Leads – Red colour

550cc RC Saturated Injectors

New Injector Seal Kit

AEM Fuel Rail – Silver

Torques UK – Custom AN6 Fuel Supply Line and Inline Fuel Filter

Fuel Pressure Gauge (1/18th NPT fitting to AN line fitting adaptor

HRC 255lph Fuel Pump

Spark Plugs – 1 step colder, 2 sets = 1 x NGK Copper & 1 x Denso Iridiums

Tuning / Electrical

Hondata S300 / P28 (with PWM boost components installed)

Jackson Racing air/fuel ratio gauge (made by Auto Meter)

Jackson Racing Oil Temperature Gauge (made by Auto Meter)

Odyssey PC680 Race Battery (for boot mounting)

Aluminium Battery Mount / custom cut off, circuit breaker, voltage tester unit / 0 gauge wiring, fuses, etc

AEM UEGO Wideband Lambda Gauge

Dyno Tune Digital Boost Gauge (accurate to within 0.1psi boost)

OEM EL Gauges, Loom, Switch, Dimming Box, etc

Pivot Blue Engine Start Button

Autometer Oil Pressure Gauge

New high & low tone horns

Cooling

Mugen Type D 1.3 bar Radiator Cap (Genuine)

Aluminium Thicker Core Radiator (97-01 5th gen fitment)

Tegiwa Import – Aluminium Radiator Stays (for top mounts)

SPAL 2 x 11” Radiator Slimline Fans

Revotec Rad Fan Fitting Kit x 2

Mugen Type F 1.3 Bar Radiator Cap (Genuine)

Mishimoto black Radiator Hoses

QH Thermostat (with new gasket)

Mikalor W2 Hose Clamps (for rad hoses) – 42mm

Millers Rxtra Cool Coolant Additive (Like Redline Watter Wetter)

AEM Water Injection Kit – No AEM Tank

5 metres of extra 6mm O.D. / 4mm I.D. Nylon High Pressure Hose for Water Injection – In Red

6mm Nylon ‘P’ Clips (for routing water injection hose from boot to engine bay)

10 Litre Red Metal Jerry Can for Water Injection Fluid

5 Litres of Distilled Water (for 50/50 mix of Methanol/Water)

5 Litres of Methanol (for 50/50 mix of Methanol/Water)

(Might not need all of the water injection stuff if chargecooler works)

Suspension

D2 36 way Adjustable Coilovers

Fully working OEM Honda Four Wheel Steering System (4WS)

Suspension Techniques uprated 25mm Sway Bars / Anti Roll Bars – Front & Back

2WS Rear Sub Frame, Control Arms, etc

Energy Suspension Master Bushing Set Installed into a Spare Set of Arms, etc – Including Rear Trailing Arms

Spoon Rear Upper Strut Brace

New Wheel Bearings

Megan Racing Adjustable Rear Toe Arms

Innovative Motorsports Competition Bar (Traction Bar)

Ultra Racing front under brace

Ultra Racing rear under brace

Exterior / Body

Full Restoration & Respray in OEM Milano Red Paint (Including Gloss Black Roof and Roof Rails, Boot OEM Spoiler & Bades Removed and Hole Smoothed, New Front Screen, Seals, Trims & Clips from Honda)

Mugen Front Bumper and Restored Mugen Emblem (Genuine)

Mugen Front Bumper / Headlight Plastic Covers (Copies)

Mugen Rear Spoiler and Restored Mugen Fixings and Emblem (Genuine)

Mugen Number Plate Screws / Washers (Genuine) x 8 for number plates and bumper fixings

Mugen Fuel Filler Cap Cover (Genuine)

Carbon Creations Carbon Fibre Bonnet – OEM Style[color]

EP Racing Bonnet Spacers

Carbon Fibre Fuel Flap

JDM Number Plates (Originals from Japan – Show use only)

Honda OEM JDM Door Window Wind Deflectors

Honda OEM UKDM Bodykit – Side Skirts

Honda OEM UKDM Bodykit – Rear Lip Skirt

Crystal clear bumper inserts - lost one side and used amber repsrayed red

Crystal clear side repeaters

Front Wiper Arms Resprayed Satin Black

Rear Wiper and Motor Removed and Blanking Grommet Installed

Aerial and Blanking Grommet Installed

Mugen Side Skirts Resprayed in Milano Red (Genuine) – just need to fabricate the last couple of small brackets

Aerocatch Bonnet Pins (Lockable)

Detango’d OEM Lights

JDM OEM Boot Number Plate Recess Panel

Mugen Side Sill Aluminium Plates (Genuine)

Honda Jazz Washer Jets

OEM Side Repeaters sprayed black

Spoon Style Fibreglass Mirrors (+ Civic Baseplates)

Spare Prelude Wing Mirrors to Butcher and make custom baseplates

AeroDynamics Carbon Fibre Sunroof Panel

Seibon Carbon Fibre Boot / Trunk

Varis Mitsubishi Evo 4-6 rear lower diffuser and side vortex generators

Wheels

No wheels currently!

Tegiwa Imports – Red Anodized Aluminium Extended Wheel Nuts

4 x 17” x 8” Volk Racing Group A Evolution 2 Alloys – 3 Piece Split Rims with Magnesium Baskets

1 x 17" x 7" Buddy Club SF Alloy Wheel (Spare Wheel)

4 x 17” x 7.5J Offset 38 – Antera 301 Alloys - Finished in Powder Coated Black with red vinyl rim tape

2 x 225/45/17 Yokohama Advan A048 track tyres (need another two!)

Interior

Mugen SW2 Steering Wheel with Integrated Cruise Control / Horn Pad (Genuine)

HKB Steering Boss with Integrated Cruise Control Buttons (Rare)

No seats currently!

Fidanza Short Throw Shift Adaptor

Custom Moulded 3 Gauge A-Pillar Pod Painted Milano Red

Front and Rear Door Card Inserts Retrimmed in Red Leathette

Handbrake Gaitor Retrimmed in Red Leatherette

Shifter Gaitor Retrimmed in Red Leatherette

JDM Flare & Holder to Passenger Side

Integra Type R Style Chrome Gearknob

Post-Facelift (94-) Chrome Door Handles

Pre-Post Facelift Transition Centre Console Conversion & Arm Rest (Rare)

Added Third Interior High Level Brake Light and Rear Roof Lining Panel

Rear interior part stripped

Centre Arm Rest - Finish Retrim

Recaro Sportline Top Fuel Specials - Grey/Black/Red

Recaro one-off 4th gen Prelude sliding seat rails (fitted to Top Fuel Recaros)

Recaro TS-G bucket seat (Japan only market seat) - Blue/Black

Recaro Japan bucket seat side mounts (Japan only market) - Black

Bride MO Sliding Seat Mounts (to fit the bucket seat to + spare)

Takata MPH-341 harness - 3" shoulder and lap straps (Genuine)

Takata 6 point V-style crotch strap (Genuine)

Tram Road Motors special Harness bar

FIA approved harness eyebolts & backing plates (4Nr for drivers 6 point harness)

Cargo Nets x 2

Brakes

Legend Calipers – Refurbed with Brakesint Kits

EBC Redstuff Pads Front

Ebay Cheap Front Discs Drilled & Grooved

EBC Redstuff Pads Rear

Bremtech Rear Discs – Drilled & Grooved

ABS removed

K Sport 6 pot Calipers - 306mm discs + Ksport pads + braided brake lines

Integra DC5 Rear Brake Calipers – Fully Refurbished

Tarox G88Rear Discs

Ferrodo DS2000 Pads Rear

Willwood Brake Bias Valve

Goodridge braided brake lines

Copper/Nickel Brake Piping to install new lines – 25ft

Various Brake items – Flare Nuts, Cutter, Bender, Flare Wrenches

8mm Aluminium ‘P’ Clips with Rubber Protector

ICE

Ripspeed 7 inch widescreen Flip Out Monitor DVD Player

JVC 100 Watts 6 ¼” 2 Way Mid Speakers to Rear Shelf

Pioneer 120 Watt 6 x 9” 2 Way Speakers in Custom Mounts (orig. 6 ¼”) in Doors

Performance

Previously dyno’d at 205.8 bhp & 152 lb/ft

¼ mile best = 15.5 seconds @ 90mph trap speed (not with a lot of mods and the weight saving I’ve done since)

Tracked as Castle Combe Circuit, Wiltshire UK

Hopeful target power after supercharger build = 300bhp+ & 210+ Torque

Hopeful target ¼ mile after supercharger build = below 13.5 Seconds

ENGINE BUILD FOR ANOTHER DAY

- Jackson Racing Supercharger kit + Motorvations 2" jackshaft pulley + Accord crank pulley = Approximately 12psi

- 106pete custom chargecooler from a Landrover SC V8 + heat exchanger rad, hoses, pump, reservoir, etc

- Benson sleeved H22A1 - 88mm bore + build up with spare H22A engine parts (50mm crank)

- Wiseco 11.5:1 88mm pistons + rings, sleeves

- Golden Eagle rods + ARP bolts

- ARP head stud kit

- Standard H22 head (unless I try a Type S / H22A7 head???)

- Full engine gasket set

- KS Tuned manual tensioner (transferred from old engine)

- Gates Powergrip belts

- ACL bearings