F22B Crank in H22

Posted: Sat Jun 06, 2015 5:59 pm

So I have a H23 crank thats been damaged from rough removal, I have been holding off getting it re-ground because of the bad stigma regrinding cranks has.

I've been looking around and it appears that the F blocks are very similar to the H. People have been removing SOHC and replacing with the H23 head ( and more rarely the H22 head).

An interesting page is https://badasstuning.wordpress.com/g23/ although re-using the head gasket sounds a bit cowboy

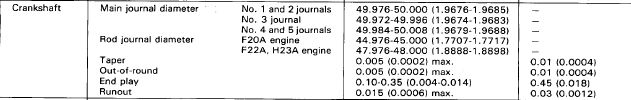

It appears that the F23 uses 55mm journals and different journal widths with a 97mm stroke, Whereas the F22 uses 50mm mains and the same width rod bearings and a 95mm stroke like the H23. As the F22 engines are available on eBay unlike the H23 I'm very tempted to buy a whole block to pinch the crank. I could possibly sell a few bits off it also.

I already have a set of 'king' rod bearings that I could then use which will help recovering some of the money I will be spending on the engine, as well as not paying for the grinding.

Does any one have any opinion on the fitment of the F22 crank? Would you normally have the journals polished when fitting new bearings? also if you think I'm wasting time with any items in my list please let me know.

My plans are;

H22 block

H22 JDM pistons new rings

H23 OEM rods with ARP bolts honed as necessary

H22 Type S head (matched to fit the bores if needed and skimmed dependent on clearance)

ARP Head studs

Type S cams

Balance shaft delete

5kg Flywheel

Under-driven crank pulley

Powerflow 2.5" exhaust (no cat)

Manual cam belt tensioner

After fitting I will look at Type S intake and 69mm TB.

I've been looking around and it appears that the F blocks are very similar to the H. People have been removing SOHC and replacing with the H23 head ( and more rarely the H22 head).

An interesting page is https://badasstuning.wordpress.com/g23/ although re-using the head gasket sounds a bit cowboy

It appears that the F23 uses 55mm journals and different journal widths with a 97mm stroke, Whereas the F22 uses 50mm mains and the same width rod bearings and a 95mm stroke like the H23. As the F22 engines are available on eBay unlike the H23 I'm very tempted to buy a whole block to pinch the crank. I could possibly sell a few bits off it also.

I already have a set of 'king' rod bearings that I could then use which will help recovering some of the money I will be spending on the engine, as well as not paying for the grinding.

Does any one have any opinion on the fitment of the F22 crank? Would you normally have the journals polished when fitting new bearings? also if you think I'm wasting time with any items in my list please let me know.

My plans are;

H22 block

H22 JDM pistons new rings

H23 OEM rods with ARP bolts honed as necessary

H22 Type S head (matched to fit the bores if needed and skimmed dependent on clearance)

ARP Head studs

Type S cams

Balance shaft delete

5kg Flywheel

Under-driven crank pulley

Powerflow 2.5" exhaust (no cat)

Manual cam belt tensioner

After fitting I will look at Type S intake and 69mm TB.