CF blanking plates made to order

Posted: Sat Mar 10, 2012 9:16 pm

So,

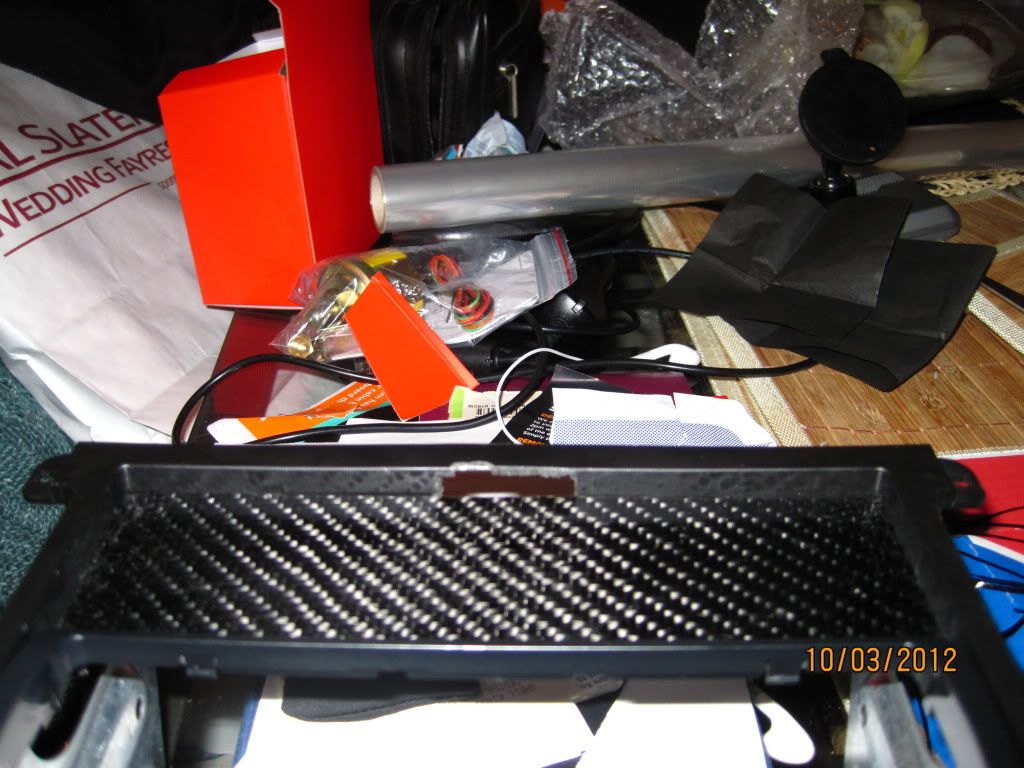

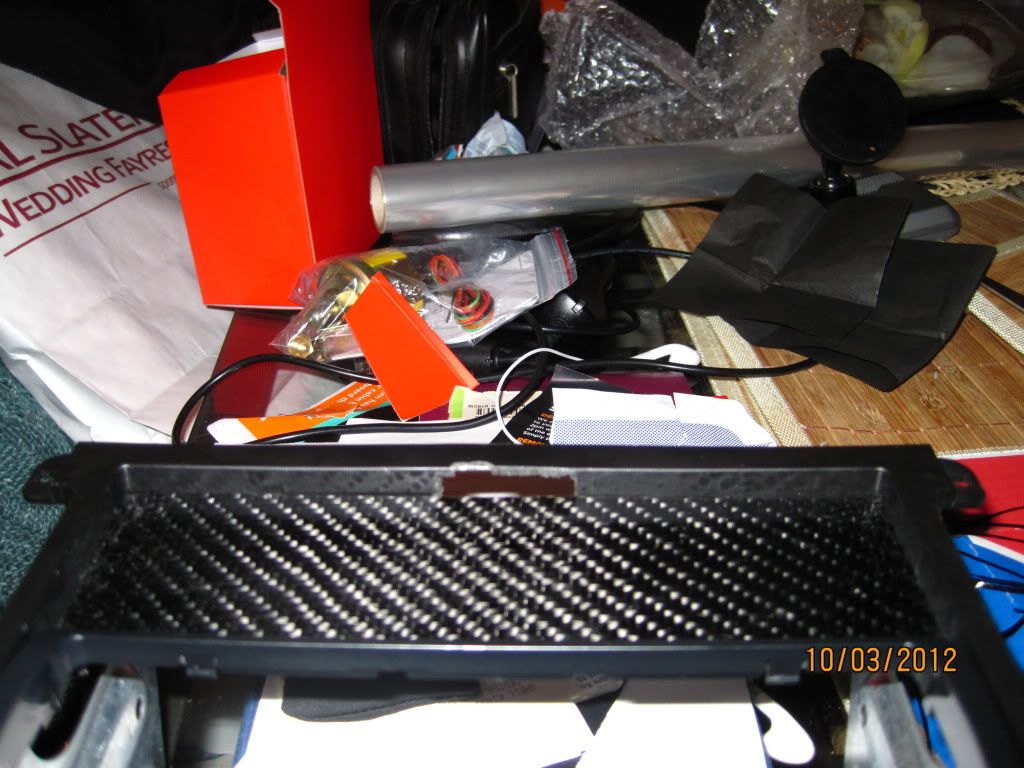

Made a CF blanking plate this evening for my CD tray so I can mount a oil pressure gauge and keep an eye on my motor

I will be cutting the hole for the gauge tomorrow so will put up more picks once this is done.

Anyway, I can make these to order very easily so if anyone want's a blank for the CD tray, stereo or both with or without holes for gauges I can do these

Prices are as follows;

Full size blank (CD tray and stereo) will be £20 delivered

Single blank for CD tray or stereo will be £15 delivered

If you want any gauge holes cut these will be an extra £5 per hole

Be aware that if you want to replace the CD tray with gauges some modification will be needed to the radio mount, but not the trim, for them to fit as the standard 52mm gauge is too big when you have the radio surround on.

The blank is made from epoxy resin and genuine 2 twill carbon fibre (the proper stuff) and is made up of 3 layers at 45 Degree orientations which gives a very strong final part

Made a CF blanking plate this evening for my CD tray so I can mount a oil pressure gauge and keep an eye on my motor

I will be cutting the hole for the gauge tomorrow so will put up more picks once this is done.

Anyway, I can make these to order very easily so if anyone want's a blank for the CD tray, stereo or both with or without holes for gauges I can do these

Prices are as follows;

Full size blank (CD tray and stereo) will be £20 delivered

Single blank for CD tray or stereo will be £15 delivered

If you want any gauge holes cut these will be an extra £5 per hole

Be aware that if you want to replace the CD tray with gauges some modification will be needed to the radio mount, but not the trim, for them to fit as the standard 52mm gauge is too big when you have the radio surround on.

The blank is made from epoxy resin and genuine 2 twill carbon fibre (the proper stuff) and is made up of 3 layers at 45 Degree orientations which gives a very strong final part