Well here's a slightly more fun update... A few little trick bits and a good bit of news... Potentially for anyone

First of all, the Skunk2 gears I had fitted recently...

I've not got a proper picture of them fitted yet as I want to get a new rocker cover and cut away appropriately first

The "bargain" £150s worth of rubber and sheet metal I bought recently

...

Then this arrived the other day, which

was potentially the last part of my new induction set up...

The plan was (being I need a new radiator), to go for a half-width radiator positioned central as possible, but allowing me to duct air from a straight line, from behind the bumper to where my filter currently sits (so basically the left side of OEM radiator) allowing as few bends as possible creating an efficient ram-air effect. In order to do this I've found the perfect "funnel"... from Tool Station

...

The rectangular intake is 204mm x 60mm and will fit perfectly in the upper grill of the front bumper. It then converts to a 5" diameter of which I will immediately adapt to 4" using this...

I had to cut a small section out in order to slot it in the "funnel". These two components will be painted black just so you know

Then when the time comes I shall use this lot to duct the air. It consists of a 102mm aluminum joiner, a 102mm-76mm Silicone reducer and a 1 metre length of 102mm diameter Silicone Ducting. I now actually have a potential means to having 102mm ends made up for my BMC-CDA filter to replace the standard 85mm ones to, but I'll get to that later

...

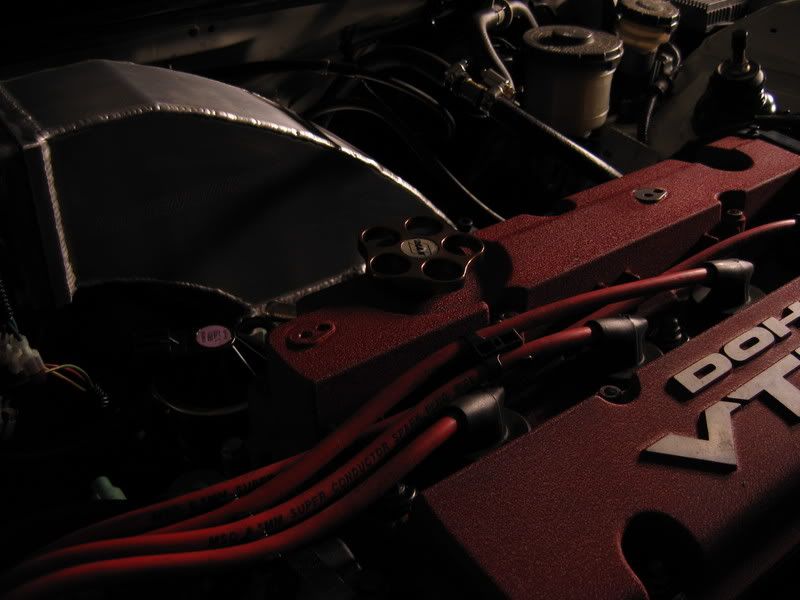

That lot will then connect to this bad boy

...

It's DH-Racing 74/68 throttle body I had shipped from the states.

It kind of speaks for itself, in that it measures 74mm across the mouth...

And tapers down to 68mm...

The idea is obviously that I'm trying to get more air into the intake manifold, and by "Ramming" air in a 5 inch diameter at one end and gradually compressing it down to just under 2 3/4 inches, the force in which it enters is also going to be greater as well.

The reason I got a second the manifold is probably going to be quite obvious as well. I need to bore out the mouth in order to match the new throttle body...

Fortunately for me I have a very good friend who is an

EXCEPTIONAL machinist and willing to do the job for me

But not only that... I took the manifold over to show him on Saturday. He'd also invited his other machinist buddy over as well as we'd already been discussing a few potential projects

My initial intention was to do as some others have already done and polish the inside of the intake manifold. You can see here how poor the casting is...

The black is obviously built up overtime, but it actually highlights exactly how rough the surface is

Anyway, you can also see how "lumpy-bumpy" the inside of the top portion of the intake is...

Ideally I'd like to fill-weld the recesses and then have everything polished allowing maximum air flow. In order to do this, the "webbing" of the top portion (The green in the next picture) would need to be cut away to give proper access. This would also mean some of the fixture points would need to be relocated. I would then be hoping to taper the webbing of the IABs to also help channel the air down. As many of you know the Skunk2 can cause a loss to lower end power due to the fact it has no IABs, so I have full intention to keep mine.

Also, I intend to do away with the EGR valve. My buddy Dale could easily whip up a capping-off plate, but the internal exits which allow the exhaust gas back into the cold air passages are still going to cause a disruption to the air flow...

Sooooooo... No sooner had I said my case... Without any hesitation whatsoever, both Dale and his pal "Vendi" (Apparently he has problems with vending machines

) Looked up from my napkin diagram and said... "Be easier to make one from scratch then?"

............

So... looks like that's the plan now lads... My very own custom built intake manifold

... And what's going to be so great about it, is that Dale puts perfectionists to shame!

He only feels something's worth doing if it out performs what's already out there (or be it at a lesser cost) and if he can make it look the dog's b*ll**ks

Also, Dale and I had already talked about the manufacture of a few aftermarket trick bits to. Dale's in the process of furnishing a newly acquired workshop of which was intended for "hobby use" with the potential of making a little money on the side. Basically he's said that he wants to help transform my engine bay, and anything he makes for me (Being my car will be the guinea pig) will also be on offer for you guys to

I'll be putting a thread together for him nearer the time. So watch this space

And, back to the last couple of bits (Won't keep you much longer

)... In ready and waiting I also have a nice and shiny AC Autotechnics 5/8" bore Fuel Rail, which will be accompanied by a power boost valve of some sort. I've not decided on whether to go FSE Power Boost valve, or a manually adjustable one of some sort yet...

And an equally shiny catch tank to hopefully keep my new intake manifold clean

...

Then last, but far from least, to eventually tie everything together, as this would probably all be pointless without it... My sparkly, newly refurbished P28 ECU

...

There you go. And now back to work I go