Hi all,

I should prob update this thread in case anyone is interested! Forgive me for copying and pasting from another forum:

So as I mentioned earlier, I’ve been meaning to improve the cooling (both oil and water) since I installed the engine as it has always ran a little hot. I often see oil temps of 105-110 on normal motorway driving for example and the fan comes on sooner than you would expect when stationary.

Coupled with the fact I don’t like the look of the tall prelude rad in the engine bay (and the fact it is still sitting on ‘temporary’ B&Q steel brackets

) I thought I would investigate other options. Here is the current look – not great:

Having looked into custom rads (quite costly) I started looking at other off-the-shelf standard radiators from other cars. I didn’t want a lude or ITR rad as they would be just as high as my current one (I can’t lower the mounting due to my traction bar). I very nearly plumped for a CRX MK2 alloy radiator as it is shorter than the lude rad, with similar hose positions etc. but I then stumbled across a radiator used in the VW Golf MKII 8v…

When I initially looked into custom rads, I thought it would be awesome if I sized it to be able to mount within the bumper void, in front of the slam panel - why not tuck it away out of sight right?! Well, the Golf rad actually gives me a very similar sized option that I would have had custom made anyway – at a much cheaper cost! Could this allow me to tuck my rad away and do something that I’d never seen done before – not even in the engine tuck world!?

Investigating this option more, I made a template out of card and mounted it to the car…

The actual cooling ability (core surface area and core thickness) of this rad would be better than the double width prelude rad I currently have (the primary reason for doing this don’t forget).

You can see that the hose positions are in a different location to normal, and it also has no filler cap.

The top hose outlet, luckily, as well as being the same diameter as the Sol (32mm ID), is in a perfect position to route the top hose through into the engine bay through the gap between the headlight and slam panel:

The bottom hose is a bit more tricky. I would have to weld a new outlet pipe from the side of the rad to enable the hose to be routed to the side of my traction bar and through into the bay up over the gearbox to the thermostat housing (the standard outlet position points right at the slam panel). Coupled with the fact that finding a very specific shaped bottom hose for this application would be nigh on impossible, this was starting to get a little tricky.

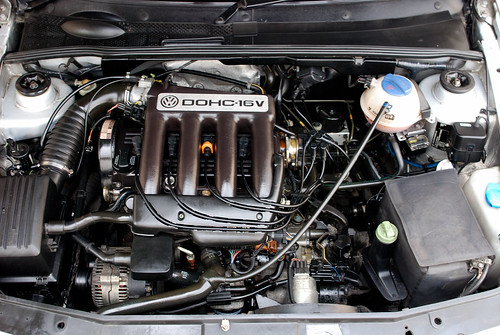

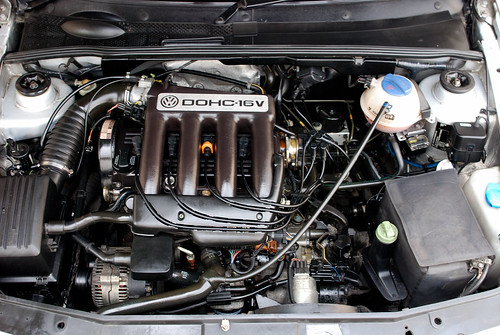

The additional problem is with respect to the lack of filler cap - the reason for this is because VW use a pressurized header tank and mount this high up in the engine bay on the right, as below;

This tank actually has two hose connections – the top one is the overflow pipe and merges into the top rad hose as shown in the photo. There is also a bottom pipe that connects to another coolant hose into the block (and to the turbo on the Golf turbo models via a Y-splitter). Reading on the VW forums quite a few people delete this tank when they tuck their engine bays and use an inline filler cap which is mounted within the top rad hose, as an alternative:

This seems to work very well for them with no daily-drive or bleeding issues so I thought I could go down the same route, as long as I make sure the rad filler cap is at the highest point of my cooling system. I decided to take the plunge and give it a go – after all I like a challenge (this whole engine conversion for starters haha

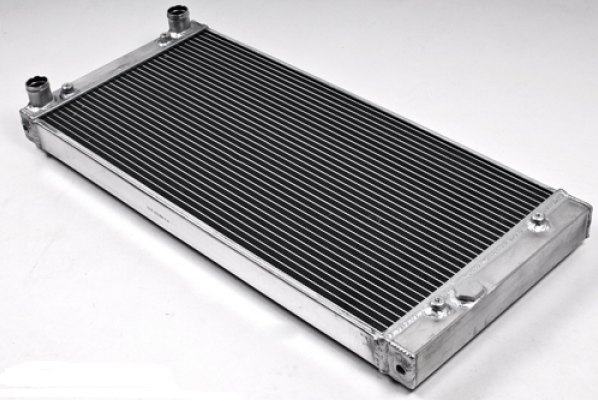

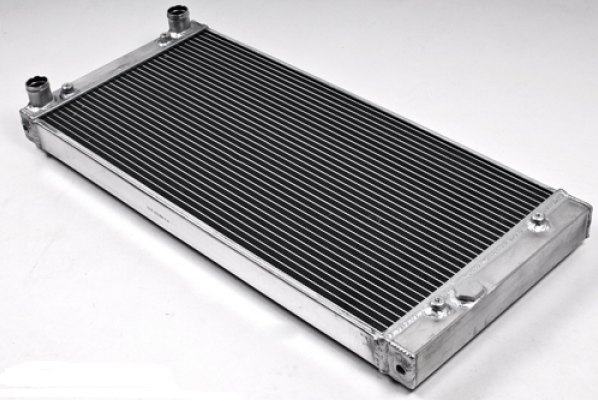

). So I bought a dual core alloy radiator online:

and test fit this into position, luckily my card template was pretty accurate:

I used a contact through my work who welds aluminium and bought a 90degree pipe:

To be welded to the side of the rad:

However even though the pipe was advertised as aluminium it turned out to be stainless steel (which can’t be welded to aluminium)

so I had the welder knock up a less-pretty solution and got a full refund from the company who false advertised the pipe;

The old outlet was also blocked up for obvious reasons:

I also had him weld brackets with M6 studs on to the rear so I can securely fit a couple of fans and not have to use those awful –through clip things which just vibrate off;

To solve the issue with finding a suitable shaped top and bottom hose to fit round all the obstructions, I found a flexible hose online with a smooth bore which looked like it could work:

At this point my MOT was due, and I had started discussions with PAW about getting it booked in along with fitting an oil cooler that I touched upon as a requirement earlier.

So that’s where I’m at – I dropped the Sol off at the weekend and Rich will be welding new brackets to the chassis for mounting both the rad and cooler, and filling and bleeding the system obviously prior to the MOT. Hoping to pick her up this Friday