I'm still working out what I think is the best way to vent the crankcase, it will probably involve a large catch can and several brake boost valves.

I rebuilt to top end of the engine with pretty much all new parts including:

- New OEM valve guides (bitch to replace apparently),

new Supertech stainless valves,

crower springs and retainers and

ATR LMA's.

The LMA's:

In place:

New valve stem oil seals:

Valves and retainers:

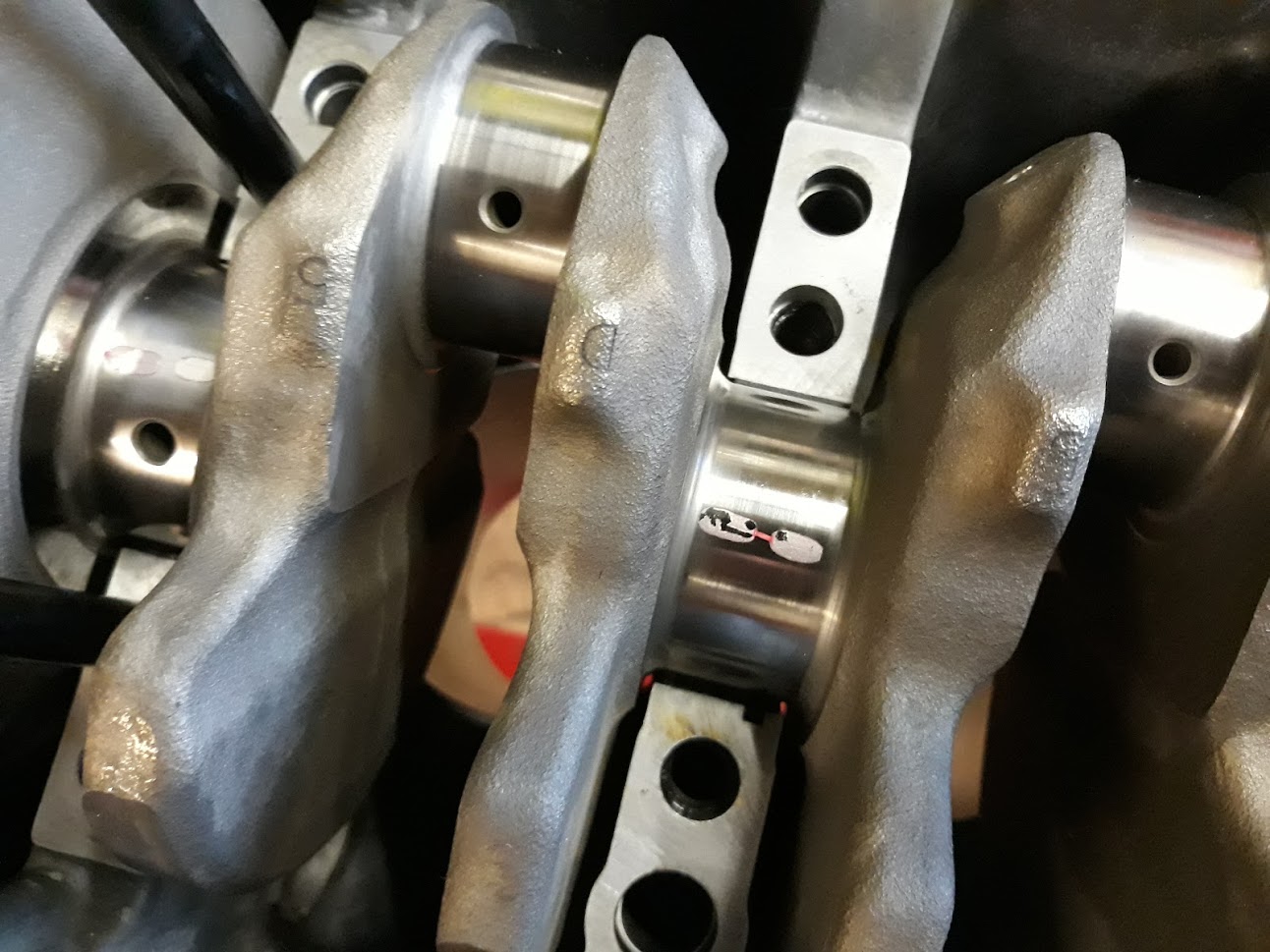

Now onto the bottom end:

Bearings:

I got the machine shop to measure everything that I needed to know the dimensions of to remove the guesswork out of fitting bearings, still I plastigauge-d everything to double check.

All was good so onto the fitting:

Piston rings:

I made mu own setup to set the correct gap on the rings, it worked really well:

Then combining the rings, pistons and rods:

And checking the gap on the rings:

And in you go...........

Coming together......

New oil pump, water pump and timing belt stuff including the balance shaft delete:

Then head meet bottom end with an OEM gasket:

And on with the cams, followers and the rest:

The rest of the cam timing gubbins in place:

Random:

Adjustable cam gears:

Random bottom:

I decided not to do the rocker cover in a solid colour:

I'e decided to fit an OEM weight flywheel:

With a new clutch:

More soon...............