Congratulations to vtecmec for winning May/June's Lude Of The Month, with his DIY Turbo BB1 build.

>>> Click Here For Profile <<<

>>> Click Here For Profile <<<

Locations for water temp / oil sensor installation?

Shortie I think (I get my filters from Honda). Can't find the thread but I think PAW said the sump was actually the best place to take oil temp from as sandwich plates/adaptors can give temp spikes (or something like that).Merlin wrote:Were you using a long or shortie filter? I thought about the sump plug as a place I could use but we thought that I wouldnt get an accurate reading from there. The extra sandwich plate solves both temp and pressure needs easily

- NafemanNathan

- LotM Winner

- Posts: 20144

- Joined: Sun Aug 08, 2010 9:37 pm

- My Generation: 0G

- Location: Yeovil, Somerset

- Has thanked: 8 times

- Been thanked: 124 times

Bit of a side thought but if you're going to use an afermarket ECU like Neptune, they have tunerview (I've got one but don't use it anymore) which you can hook up and configure to show readouts of any sensor the ECU is connected to. Hondata might do something similar, or tunerview might even work with Hondata.

- h10ndr

- Posts: 819

- Joined: Mon Sep 13, 2010 7:07 pm

- My Generation: 4G

- Location: West Yorkshire

- Has thanked: 1 time

- Been thanked: 10 times

- Contact:

Tunerview does work with Hondata...

"Now Natively Supports S300 and K-Pro With Controller Module (Add-On).

Supports NepTune, NepTune RTP, eCtune, Crome, and Uberdata "

"Now Natively Supports S300 and K-Pro With Controller Module (Add-On).

Supports NepTune, NepTune RTP, eCtune, Crome, and Uberdata "

Tim

2004 S2000 GT Berlina Black

SOLD 1992 JDM-BB1UKSPEC-B545P-H22A7-U2Q7-P72 NEPTUNE RTP

RIP 1995 UKDM-BB1-Pacific Blue Pearl

http://www.s2000-parts.com

Profile

2004 S2000 GT Berlina Black

SOLD 1992 JDM-BB1UKSPEC-B545P-H22A7-U2Q7-P72 NEPTUNE RTP

RIP 1995 UKDM-BB1-Pacific Blue Pearl

http://www.s2000-parts.com

Profile

-

PerformanceAutoworks

- Posts: 259

- Joined: Mon Jan 30, 2012 9:24 am

- My Generation: 4G

- Location: Fairford, Glos

- Has thanked: 4 times

- Been thanked: 3 times

- Contact:

Out of the three things that Merlin is trying to monitor the ECU only "sees" ECT (Engine coolant temp).judderod wrote:Bit of a side thought but if you're going to use an afermarket ECU like Neptune, they have tunerview (I've got one but don't use it anymore) which you can hook up and configure to show readouts of any sensor the ECU is connected to. Hondata might do something similar, or tunerview might even work with Hondata.

ECU does not read oil pressure or oil temp.

Back onto where/when/how...

You can either use a "sensor" sandwich plate under or on top of your oil cooler sandwich plate - there is room to do this..just... and fit your oil temp and pressure sensors in here. Pressure readings are usually good but oil temp is not as stable a reading here and can spike showing a little hotter than it actually is. It's ok but I prefer more stable readings that the sump actually offers.

Drill and tap a sump plug right through and run you temp sensor in that. Some will say the "blind drilled" option is better for safety but I find this method reads a little low. Obviously if you are feeling adventurous you can drill the sump and weld a boss (or tap the sump if an alloy one) onto it to allow a temp sensor fitment seperate from sump plug but that will obviously require sump removal.

Or

Pressure Sender

Junk the OEM idiot light and fit your oil pressure sensor here. Why do you even want to keep the OEM light? if that comes on at any speed it's usually too late anyway (6psi or lower to bring it on). Most oil pressure gauges of any quality will have some kind of low pressure alarm (flashing light, buzzer etc).

Or

If you do want to keep the two then DO NOT fit a brass T-piece adapter straight into the block...as has already been said, these can break off quite easily through the weight of sensors and vibration. Mount a T-piece remotely and attach to block via braided line.

Or

You can tap into the oil pressure feed at the cylinder head - there are two ports at the back of the head and one at the front (left hand side). I don't favour this mostly because it looks messy but readings will be pretty consistant.

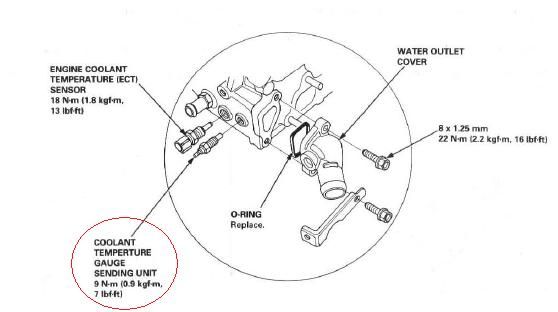

Coolant temp - Not a fan of in line hose connectors as a sensor mount. They are too easily affected by outside factors (manifold, cool air rushing over them etc). Best bet is remove thermostat housing, drill and tap the bleed screw location to accept your temp sender and fit it there. Neat, tidy and accurate.

Bleeding the coolant on these engines is not the rocket science probematic experiance that people seem to think. If the bleed screw location is used for temp sensor then all you need to do when filling with coolant is to remove the small bore IACV coolant hose from it's outlet right next to the bleed screw. This will do exactly the same job as the bleed screw and is no more difficult to achieve.

In case it's of any use, Neptune can configure the ECU to monitor up to 4 aux inputs, as well as the O2 sensor, so you can use these for oil temp, pressure etc. I'll be using one for a MAP sensor in a ram air intake during development so I can see the effect on dynamic intake charge pressure.

The benefit with doing it this way is you can set thresholds for the ECU to react eg. limp mode/CEL below a set oil pressure/above a set temp.

The benefit with doing it this way is you can set thresholds for the ECU to react eg. limp mode/CEL below a set oil pressure/above a set temp.

- Merlin

- Moderator

- Posts: 12393

- Joined: Fri Aug 06, 2010 9:04 am

- My Generation: 5G

- PSN GamerTag: Merlinbadman

- Location: Edinburgh

- Has thanked: 68 times

- Been thanked: 303 times

PerformanceAutoworks wrote:Coolant temp - Not a fan of in line hose connectors as a sensor mount. They are too easily affected by outside factors (manifold, cool air rushing over them etc). Best bet is remove thermostat housing, drill and tap the bleed screw location to accept your temp sender and fit it there. Neat, tidy and accurate.

Bleeding the coolant on these engines is not the rocket science probematic experiance that people seem to think. If the bleed screw location is used for temp sensor then all you need to do when filling with coolant is to remove the small bore IACV coolant hose from it's outlet right next to the bleed screw. This will do exactly the same job as the bleed screw and is no more difficult to achieve.

Sorry to have to tag you again, I know you are always busy

What about using the place for the OEM water gauge sensor? Can I just pull out that sensor, install my own one and run it to my aftermartket water temp gauge? I assume the ECU gets all its info from the engine coolant temp sensor directly next to it, leaving the gauge sensor to only send info to the OEM gauge?