Rob, FYI this was Kris (Edu's) original 4 pin ECU and the chip you sold him (he bought a 3-pin ready chipped ECU and stuck that in instead).

I still haven't got round to doing anything with the chip I bought off you about 3 years ago for my UKDM

Nb: the large code on the chip is the wrong kind (not C3) but I decided to try it anyway

EDIT:

Robs instructions are very good, but I took the opportunity to take a few pics so here's my guide. Rob, if I've :spammed: the drokk out of your thread

I'll add to comments from others that installing it yourself isn't the easiest job in the world - I was trained in soldering/electronics at college and am quite experienced (for a DIY'er) but I also had a mate help who's apprentice trained/qualified elecronics technician and spent 15 years repairing electronic equipment and it certainly wasn't the easiest job either of us have done. If you're not confident and PATIENT, follow Rob's advice and get an electronics repairer (or bluejackhustler) to do it for you.

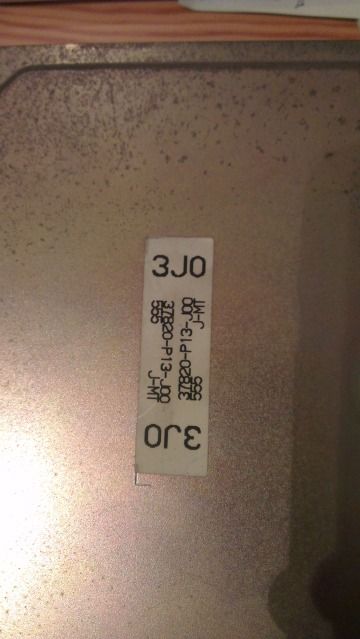

Looking at the old chip;

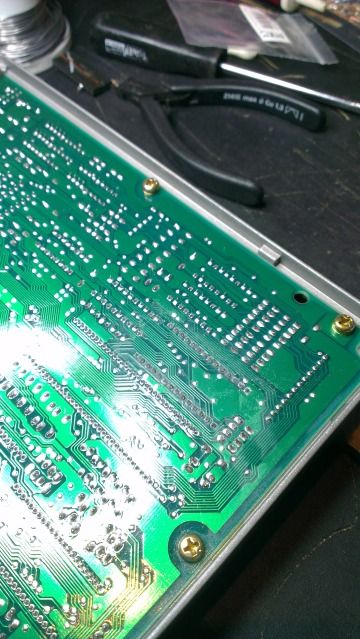

Tried to get the old chip out in one go (to keep as a spare) by unsoldering, but the board is very (comparitively) thick so drawing the solder out completely from inside the holes/the other side of the boards just wasn't happening. Others have done it, maybe we were particularly unlucky with this ECU, who knows, but either way, the chip made what LLL would describe as a one way trip;

Which left the legs in the board;

If you're going this method, you need small and very sharp/strong side cutters. Do it before trying to de-solder the back of the pins first, because it means they're securely held in and unlikely to damage the board/track pads while cutting (it's quite a violent shock when they cleave). The pins are then really easy to unsolder and remove (use tweezers to lift them out).

You then need to clean up the pads properly and clean out the holes, which takes a long time and you need patience! The pads are small so need to be careful not to overheat them, which could damage or cause them to lift off;

NB: We found (much to my distain) that solder suckers aren't any good for any of this job, you need de-solder braid/wick.

The PCB in the ECU is heavily lacquered (for strength and to cope with the moisture/vibration that you get in a car) so after all the solder is clear, clean everything off to remove flux/lacquer/other crap with electro-clean and a decent rag or cotton bud that won't leave fibres everywhere. Be gentle though, so as not to damage any tracks.

Then you can insert the new holder and re-solder on the back. As it's a multi-layer board, you need to make sure that enough solder is applied so that it runs properly through the hole to the other side, but don't overload it.

Note in the second pic that on my ECU, the small ancilliary PCB that mounts vertically at the end of our chip was leant forward slightly and overhung the end of the socket. There was no way that the new chip would fit into the socket (overlap was about 2mm

Not all ECU's have this style of ancilliary board - some have a 'potted' board from what I can make out, and they don't overhang, so you may get lucky.

After everything is finished, clean off again to remove any flux from the solder and then you can relacquer (available from Maplins, about £4). Don't have to, but it's advisable. Avoid spraying lacquer onto the top of the chip/legs though.