Congratulations to vtecmec for winning May/June's Lude Of The Month, with his DIY Turbo BB1 build.

>>> Click Here For Profile <<<

>>> Click Here For Profile <<<

H22A EG LSI Track Project

- Stealthdog

- Posts: 133

- Joined: Wed Feb 11, 2015 6:52 pm

- My Generation: 4G

Re: H22A EG LSI Track Project

Cheers pal no my plenum is an accord type r with 76mm tb, the fuel lines are tucked Earls race plumbing by Holley

- Stealthdog

- Posts: 133

- Joined: Wed Feb 11, 2015 6:52 pm

- My Generation: 4G

Re: H22A EG LSI Track Project

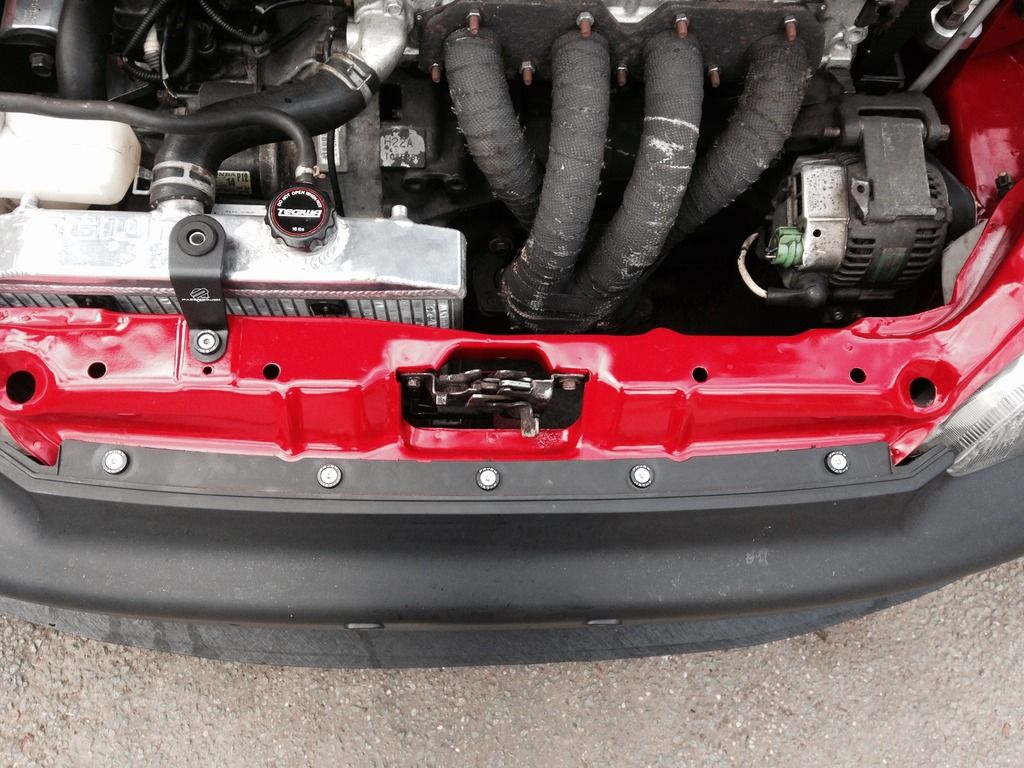

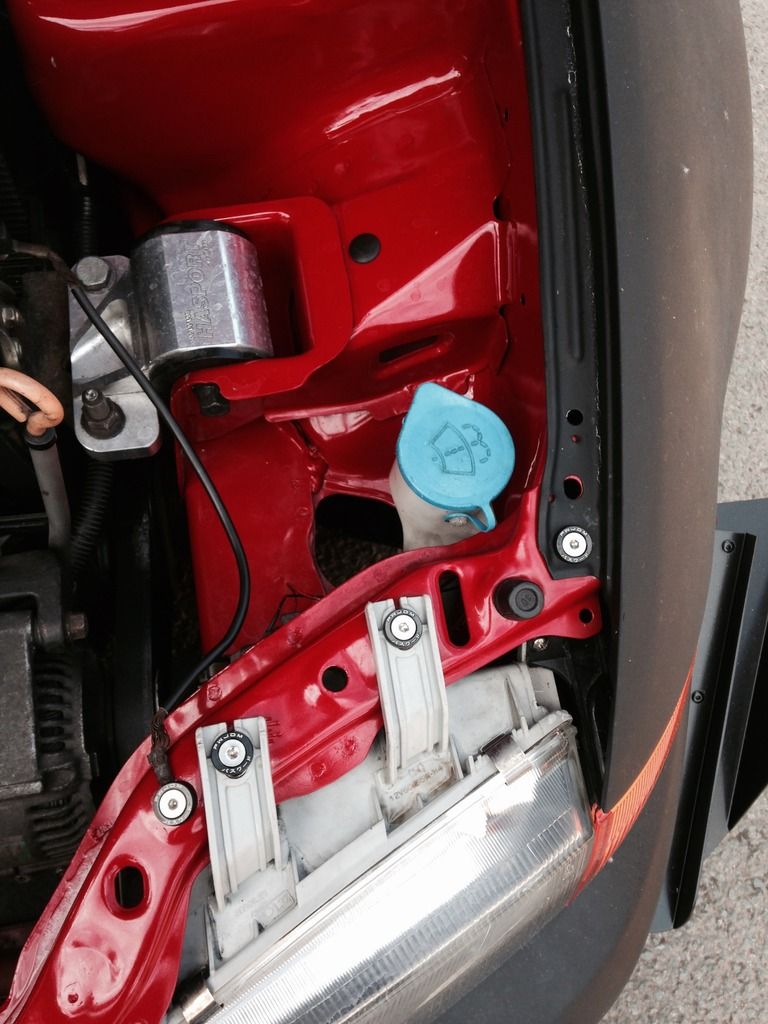

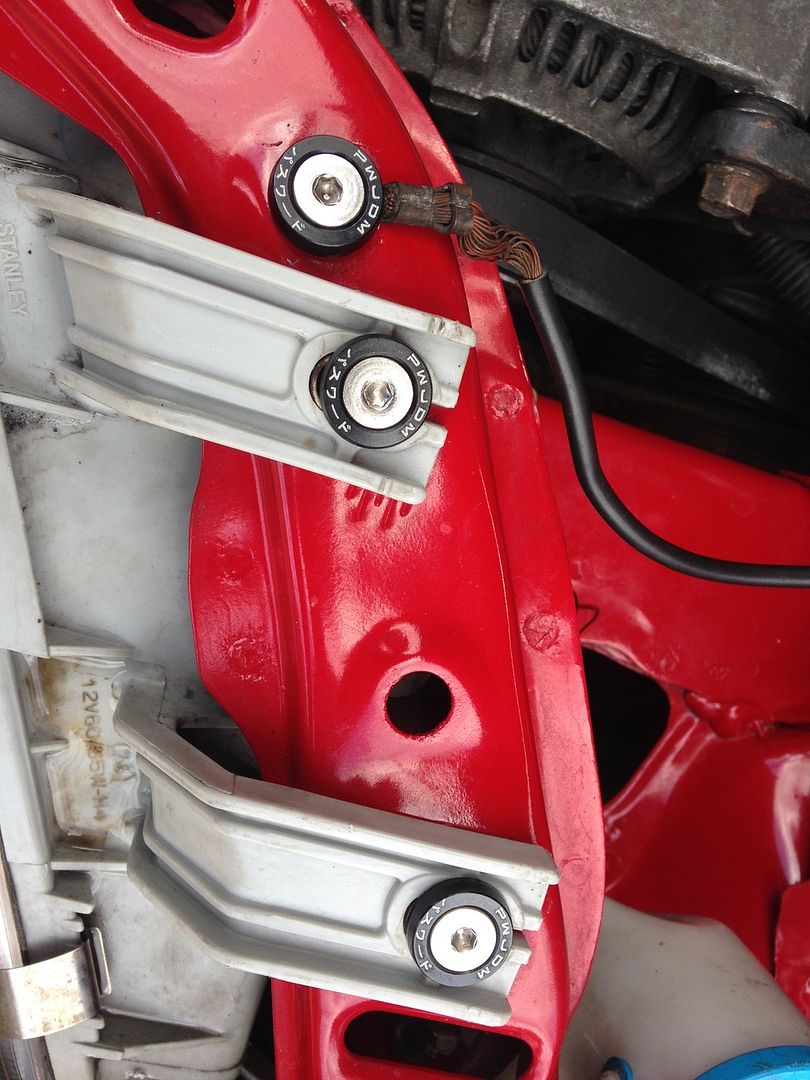

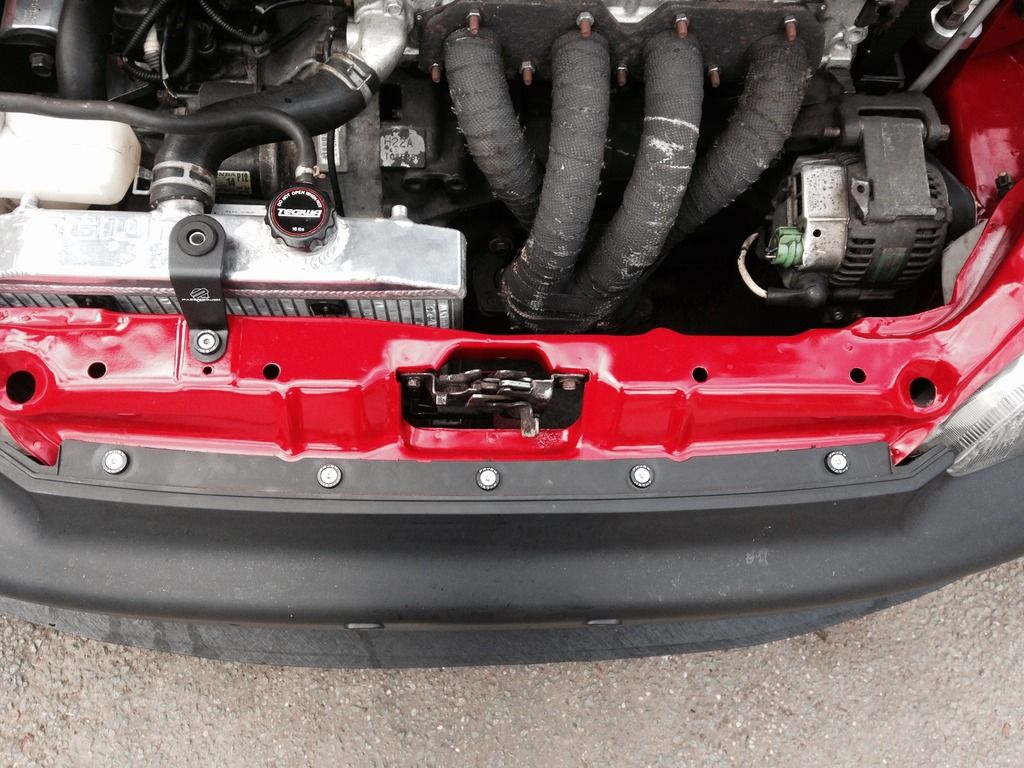

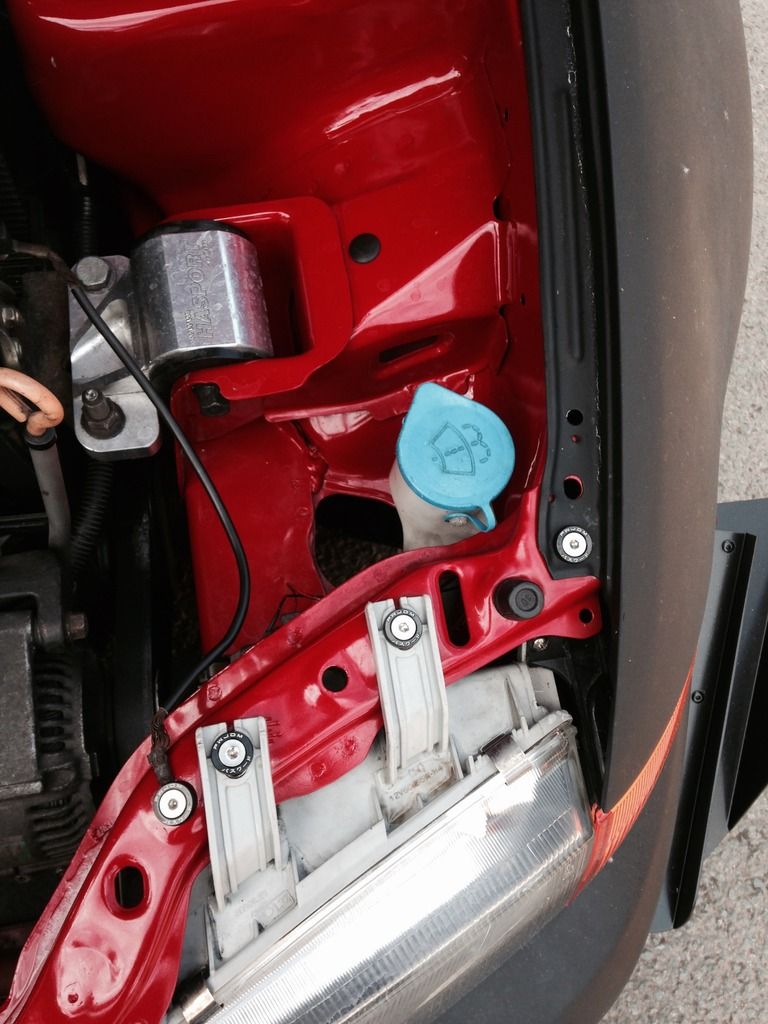

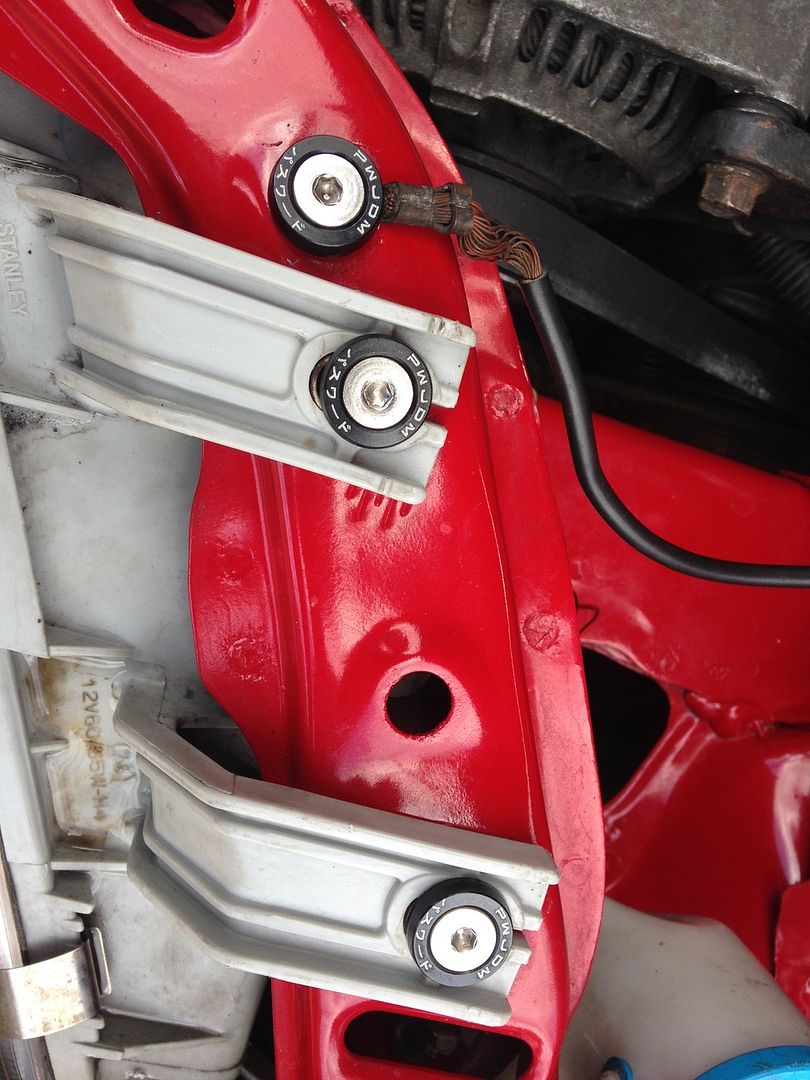

So more goodies arrived yesterday and I set about fitting them, password jdm flush washers and bumper quick release's and black type R weighted gear knob.

- wurlycorner

- Ye are glad to be dead, RIGHT?

- Posts: 21224

- Joined: Sat May 19, 2012 3:33 pm

- My Generation: 4G

- Location: Chelmsford, Essex

- Has thanked: 1968 times

- Been thanked: 240 times

- mercutio

- LotM Winner

- Posts: 14958

- Joined: Sun Aug 08, 2010 8:45 pm

- My Generation: 5G

- Location: Sunny Manchester

- Has thanked: 1 time

- Been thanked: 3 times

- Contact:

the bolts are plain its the washers that are anodised and he could always put a plain washer under the dress up one

bristol_bb4 wrote:ahhh a 5th gen, i love 5th gens

Dino wrote:I loves the 5th gen really.... just dont quote me on it...

4thgenphil wrote:Mines 4 1/4 unches mate, sorry

http://www.ludegeneration.co.uk/profile ... -t618.html

- wurlycorner

- Ye are glad to be dead, RIGHT?

- Posts: 21224

- Joined: Sat May 19, 2012 3:33 pm

- My Generation: 4G

- Location: Chelmsford, Essex

- Has thanked: 1968 times

- Been thanked: 240 times

That's true, however every additional surface contact you put in place adds resistance and likelihood of corrosion build up reducing that even furthermercutio wrote:the bolts are plain its the washers that are anodised and he could always put a plain washer under the dress up one

--

Iain.

Iain.

Super Secret 1G (not really super secret!)

- mercutio

- LotM Winner

- Posts: 14958

- Joined: Sun Aug 08, 2010 8:45 pm

- My Generation: 5G

- Location: Sunny Manchester

- Has thanked: 1 time

- Been thanked: 3 times

- Contact:

just be the same amount of surface contacts? the washer and the car body.

bristol_bb4 wrote:ahhh a 5th gen, i love 5th gens

Dino wrote:I loves the 5th gen really.... just dont quote me on it...

4thgenphil wrote:Mines 4 1/4 unches mate, sorry

http://www.ludegeneration.co.uk/profile ... -t618.html

- wurlycorner

- Ye are glad to be dead, RIGHT?

- Posts: 21224

- Joined: Sat May 19, 2012 3:33 pm

- My Generation: 4G

- Location: Chelmsford, Essex

- Has thanked: 1968 times

- Been thanked: 240 times

Yep, fair do's, if you have a guaranteed good contact between the crimp and the body, you're right you don't need the other path. But people tend to not clean the paint off under where they fit an earth, or those surfaces get corroded so the contact ends up being made through; crimp to bolt head - bolt thread to body (2 surface contacts).

If you have a washer fitted the contact surfaces are crimp to washer - washer to bolt head - bolt thread to body (3 surface contacts).

But yep, if the paint is properly cleaned off under that crimp eyelet and the eyelet is properly cleaned from corrosion, what's currently there will work.

It won't last though, so you should always have the extra path via the washer and bolt, which the anodised washer completely blocks.

So you could change it for a plain washer, but that is also less good than no washer.

If you have a washer fitted the contact surfaces are crimp to washer - washer to bolt head - bolt thread to body (3 surface contacts).

But yep, if the paint is properly cleaned off under that crimp eyelet and the eyelet is properly cleaned from corrosion, what's currently there will work.

It won't last though, so you should always have the extra path via the washer and bolt, which the anodised washer completely blocks.

So you could change it for a plain washer, but that is also less good than no washer.

--

Iain.

Iain.

Super Secret 1G (not really super secret!)

- Stealthdog

- Posts: 133

- Joined: Wed Feb 11, 2015 6:52 pm

- My Generation: 4G

H22A EG LSI Track Project

There is contact beneath the washers as I had reemed out the paint for perfect contact and there's a plain flat washer beneath the earth contact

- NafemanNathan

- LotM Winner

- Posts: 20144

- Joined: Sun Aug 08, 2010 9:37 pm

- My Generation: 0G

- Location: Yeovil, Somerset

- Has thanked: 8 times

- Been thanked: 122 times